After rebuilding the pump I found out the old cast impeller cant be used w the new seal.

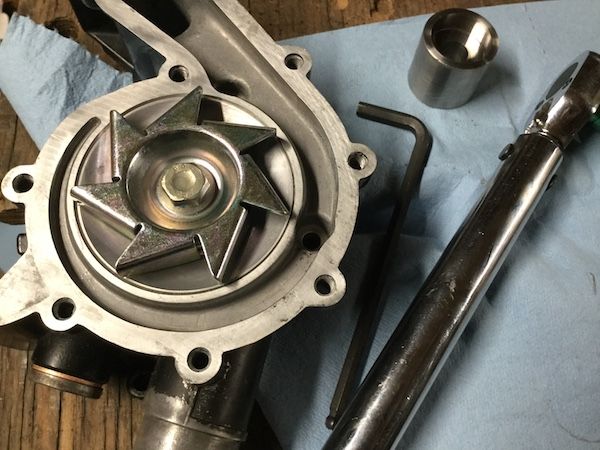

Also, after the first rebuild. The pump wasnt leaking but I didnt feel very confident about using sockets and a hammer to pound the seal onto the shaft. (youtube "DIY" vids) So asked my buddy to make me a proper installation tool.So rebuild 2.0.

Upon disassembly I tore the seal apart to see how it was made.

As suspected I Found it is a VERY fragile thing. Its made up of 9 separate components. A ring inside actually appears to be nothing more than a brittle, soft compressed graphite like material. Its soft enough that I can write with it like a pencil. And crack it to pieces w my fingers.

Probably easily damaged under percussive shock of using a hammer to beat it onto the shaft.

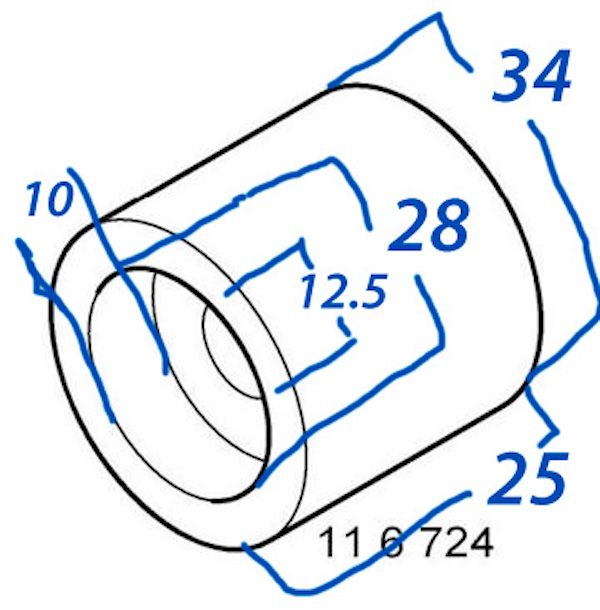

Installation tool. The OD of 34mm is bare minimum. It can be up to 40mm OD.

I lubed up the oil seal and shaft w 90w and installed them.

Then thoroughly cleaned and dried the shaft w acetone. So the coolant seal wouldnt be prone to spinning on the shaft once fitted.

Rather than pounding the thing w a hammer. Or, fumble farting around trying to turn it onto the shaft using the bolt.

I used a C-clamp to gently press the seal onto shaft and into housing at the same time.

This method worked out GREAT. I am really confident about the job.

Filled the small space between the seal and shaft w Permatex water pump sealer.

Filled the small space between the seal and shaft w Permatex water pump sealer.

Torqued to 33nm and ready to go on the bike.

Dont know if its for the best. Maybe threebond would be better. But, Using Ultra black to seal oil pump/engine surfaces and waterpump sealer on the cover side.